What is the difference between woven and printed labels?

The main difference between woven and printed labels lies in the production process and the resulting appearance and feel of the label:

- Production process:

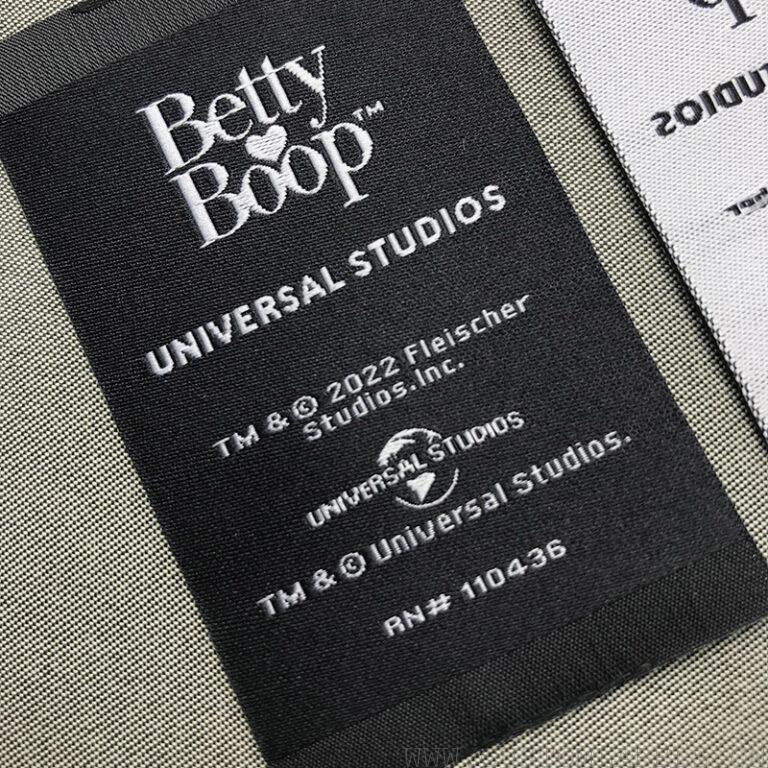

- Woven labels: Woven labels are created by weaving threads together on a loom. The design and text are woven directly into the label using different colored threads. This process allows for intricate and detailed designs with durable, long-lasting results.

- Printed labels: Printed labels are produced by transferring ink onto the label material using various printing methods such as screen printing, digital printing, or heat transfer printing. This process allows for more flexibility in terms of design, color, and customization options.

- Appearance and feel:

- Woven labels: Woven labels have a textured, tactile feel. They are typically thinner and flexible, making them suitable for delicate or stretchy fabrics. The woven threads give a high-quality, professional appearance to the labels.

- Printed labels: Printed labels have a smooth, flat surface. They can be made with different types of materials, such as satin, cotton, or polyester. Printed labels can accommodate a wide range of colors, gradients, and intricate designs, resulting in a visually rich label.

Consider the following factors when deciding between woven and printed labels:

- Design complexity: Woven labels are better suited for intricate designs, while printed labels offer more flexibility in design details and color options.

- Fabric type: Woven labels are more suitable for delicate or stretchy fabrics, while printed labels can work well on various fabric types.

- Durability: Woven labels tend to be more durable and long-lasting, as the design is woven into the label itself. Printed labels may fade or wear off over time, especially with frequent washing or exposure to harsh conditions.

Ultimately, the choice between woven and printed labels depends on your specific preferences, design requirements, and budget.