How to check the quality of woven labels?

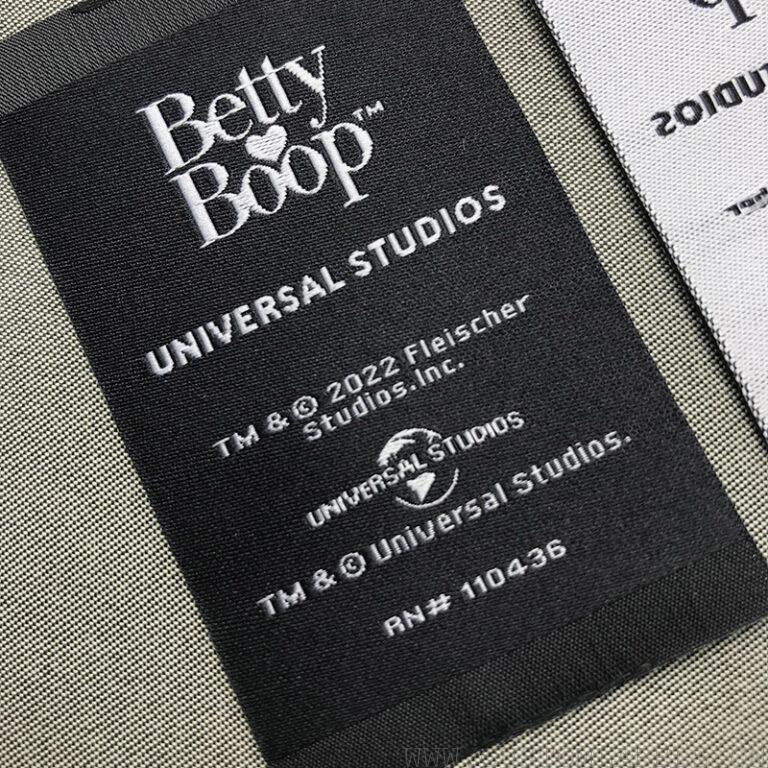

Let’s first check whether the pattern and text on the woven labels are correct and whether the size of the pattern and text is correct. At first glance, check whether there are any errors or omissions in the pattern and text content of the woven label. Of course, these low-level errors can usually be found at the beginning of the printing process. Such low-level errors will not occur when delivering bulk goods to customers. . Then, the next step is to see whether the pattern and text woven from the woven label are fine. The effect of each picture and text is exactly the same as the original version or original picture, which means that the woven label is quite successful because it can meet the customer’s needs from the pictures and text. It is very important to meet the customer’s needs through pictures and texts. If the pictures and texts cannot achieve the effect that the customer wants, the woven label is unqualified. To the customer, it is a defective product. No customer can handle the defective product. accept.

The pattern must not only meet the requirements in shape, but also in size. The woven label itself is very small, and the size of the pattern sometimes needs to be accurate to 0.05 mm. If it is slightly larger by 0.05 mm, then the woven label will be the same as the original. The comparison is out of shape. Of course, some customers may accept a difference of 0.05 mm on the woven label, but for some high-end brands, a difference of 0.05 mm is not enough. It must be accurate because the woven mark is a long-term word-of-mouth carrier, which carries the brand name. , the exquisite and rigorous spiritual characteristics of the brand are inside. On the brand clothing, this kind of woven label is a tangible word-of-mouth publicity and an intangible carrier of the brand spirit. So don’t ignore the power of a small woven label, which is exquisite and professional.

Secondly, look at the color of the woven labels. The color is generally the Pantone color system. The color comparison here is based on the original color or the Pantone color number of the design draft. There is no special explanation on this point, and we can only rely on sensory judgment.

Third, look at the density of the woven label. The density of the woven label refers to the weft density. The higher the weft density, the higher the quality of the woven label. Weft density refers to the number of yarns in the woven label within 1CM. The finer the yarn, the finer the woven label. The fine woven label has a very high brand and is a high-end woven label. Yarn usually uses D to represent its thickness. 100D is thicker, 75D is thinner, 50D is thinner yarn, and 30D is the thinnest yarn.

Fourth, look at the post-process processing of woven labels. The post-processing steps of woven labels generally include cutting (hot knife cutting), super-cutting (ultrasonic cutting), shearing (cutting one by one, and then folding the left and right sides inward by about 0.7CM each), folding in half (folding symmetrically), and molding. (It is to cut a square woven mark into an irregular pattern shape, such as a woven seal. It is cut into molds one by one with a knife or laser gun), starching (that is, to put the woven mark on the container) Dip the inside of the milky white pulp bucket, and then let the woven label dry or air-dry. After the pulp on the woven label dries, the woven label will become tougher), and overlock (that is, seal the 4 sides of the woven label with thread) , to prevent future unraveling).

These post-processing steps determine whether the post-weaving processing steps pass the test. The customer requests which post-process to choose and whether it meets the post-process processing requirements. For example, it is necessary to reach the front of the woven label without cutting hands. Over-cutting cannot loosen the edges. When cutting and folding, both sides must be neat and not skewed. Folding in half needs to be symmetrical, not one long and one short. The ring mold must be cut according to the pattern, and the pattern cannot be cut. In the sizing process, some customers require that after sizing, the woven label should not be too hard, so the sizing personnel need to put less pulp and more water to make the slurry water thinner. When overlocking, the overlocking line cannot be locked to the pattern.